Boiler Mountings

These are different fittings and devices which are necessary for the operation and safety of a boiler. These devices, usually are mounted over the boiler shell. According to I.B.R, the following mountings should be fitted to the boilers

- Two safety valves

- Two water level indicators

- A pressure gauge

- A steam stop valve

- A feed check valve

- A blow-off cock

- A manhole

- Mud holes or sight holes.

- Fusible plug

Lancashire and Cornish type Boilers should be fitted with high pressure and low water safety valve.

All land boilers should have a fusible plug in each furnace.

The various mountings are discussed as follows:

1. Water level indicator

Function:- The function of a water level indicator is to indicate the level of water in the boiler constantly.

Construction: Fig shows the details of a water level indicator. It is fitted on all types of boiler. It is fitted at the front end of the boiler so that it is visible to the operator.

AB is the front end plate of the boiler. W is the boiler water level. Fig shows Hopkinson's water gauge. F is a strong glass tube covered with a tough or guard glass (L) for protection, It indicates the water level. It is connected to the boilerplate, through stuffing boxes in hollow gunmetal castings (B and C). X and Y The flanges used for bolting the plate.

Plate AB is provided with holes with inside threading for screwing these castings. The upper casting communicates with the steam space of the boiler. The lower casting communicates with the water space. These two passages are controlled by two cocks D and E These passages are open when the handles of these cocks are vertical (See Fig) A hollow gun metal column or tube G is provided in the center of the hollow gun-metal castings. This column is fitted with third cock K. It is known as drain cock or blows through cock. When the handle of this cock is vertical it is closed. H and J are two hollow gun-metal balls. Balls H and J are in the positions shown by a full circle when the gauge is in the normal working condition M, N, P and R are screwed plugs. They are provided to clean out, when necessary, of the tube and castings.

Working:- When the cocks D and E are opened, steam rushes from the upper passage in B and water rushes from the lower passage in C to the glass tube F. Both of them adjust their levels. This will indicate the level of water in the boiler. In hollow gun-metal column G, the water also stands at the same level.

In case, glass tube F gets broken, the steam will rush from the upper passage and the water from the lower passage because of the pressure difference between boiler pressure and atmospheric pressure. This water carries the hollow gun-metal ball J from its normal position to the position shown by a dotted circle (see Fig.) This will close the passage of water to the glass tube. Now the water rises in the hollow gun-metal column G. This water aided by the steam rushing through the upper passage will carry the ball H from its seat and placed it to the new position shown by a dotted circle. Hence the supplies both water and steam to the glass tube Fare closed. The glass tube F can be replaced by closing two cocks D and E.

The water level indicator used for high-pressure boiler should be provided with guards made of thick toughened glass which covers the front and sides of the glass tube. The boiler attendant is then protected from the flying fragments of glass when a glass tube bursts.

2. Pressure Gauge

Function: The function of pressure gauge is to measure the pressure exerted inside the vessel OR boiler shell.

Construction - Fig shows the details of the construction of the interior of Bourdon's Pressure gauge. This gauge is generally fitted on the front side of the boiler shell. It is fitted to the steam space of the boiler shell with the help of an inverted siphon. It is usually constructed to indicate up to double the maximum working pressure. Its dial is graduated to read pressure in bar gauge (i.e. above atmospheric). The syphon of the gauge is always full of water or condensed steam.

It consists of a Bourdon's spring tube ABC. It is made of copper and bent into a circular shape. This tube has an elliptical section. The end A of the tube is plugged. The other end C is connected to a hollow block E. The lower portion of this block is threaded. The block E has a small opening for the entrance of steam or water from the boiler. The end A is connected to the link R. This is pivoted hinge at H. This carries a toothed sector. This can swing about H. The small pinion meshes with this sector, Pinion carries a pointer P fitted on its spindle. To Indicate the pressure of steam inside the boiler, this pointer moves on a graduated dial or scale. The pressure gauge components are enclosed in a circular dial casing.

Working: The movement of the free end of the elliptical tube is proportional to the difference between external and internal pressure on the tube. Since the outside pressure on the tube is atmospheric, the movement of the free end is a measure of the boiler pressure above atmospheric i.e gauge pressure.

The pressure gauge is connected with the boiler's steam space through U-tube syphon. The U-shaped syphon pipe contains water which fills the Bourdon tube. The pressure of the steam acting through the water on the inside of the tube tries to make the tube circular. One end is fixed, the free end moves. The movement at the free end is proportional to the difference in pressure as shown above. Because of pinion and gear arrangement, the slight movement of the Bourdon tube is magnified considerably and the point gives a maximum deflection that can be read on the scale.

The water in the U-tube syphon prevents the steam from coming in contact with the spring tube. This will reduce overheating and thermal stresses in the spring tube. A three-way cock is provided for connecting the boiler pressure gauge to the steam space.

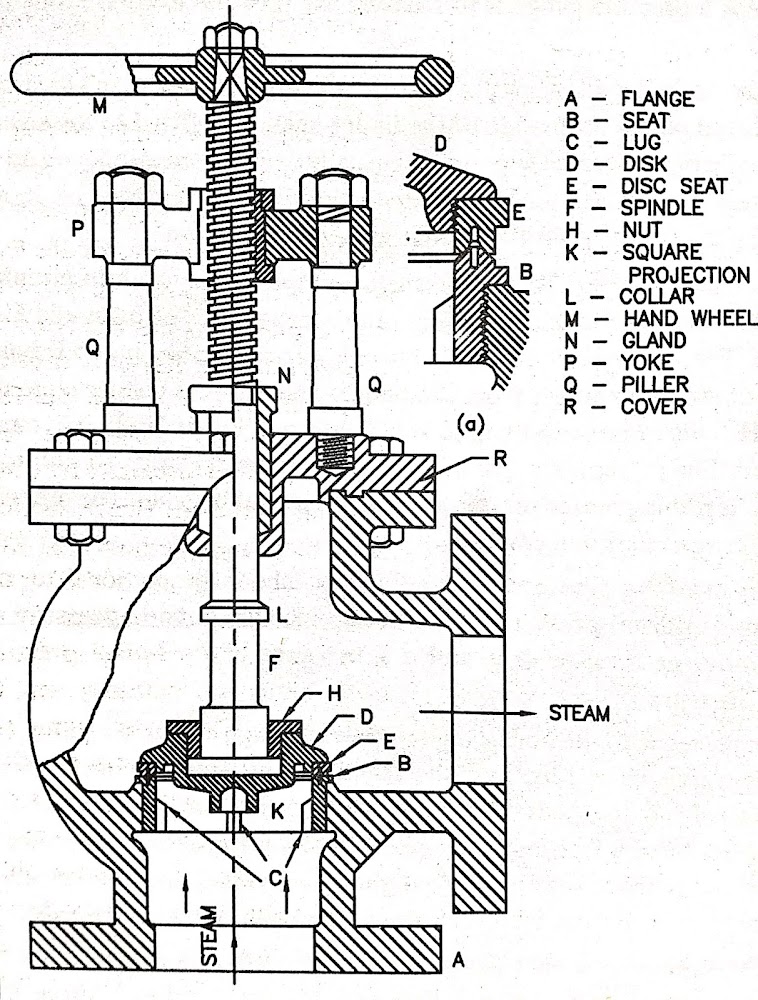

3. Steam Stop Valve

What is a Junction Valve?

The steam stop valve when directly mounted on the steam space of the boiler shell and connected to the steam pipeline which supplies steam to the prime-mover is called a Junction valve.

Construction - As shown in the figure the flange A of the body is bolted to the boiler at the highest part of the steam space. The seat B is screwed into the body with the help of lugs C cast on its interior. Disc D has a renewable disc seat E. This seat E is screwed on to the disc D. The construction of seat is shown at (a). The valve disc D is connected to the spindle F by the nut H. The lower edge of the nut H is in contact with a collar on a lower end of the spindle. The spindle carries the disc D with it (as it is raised or lowered). But it is free to rotate within the disc.

The spindle passes through a gland and stuffing box (N) in the cover of the body. The upper portion of the spindle is screwed and passes through a nut in the crosshead or yoke P as shown in the figure. To the top of the spindle, a hand wheel M is fitted. The spindle F is square threaded. The nut is mounted over two pillars Q. The valve is operated by a hand wheel (M).

Working: When the hand-wheel is turned in an anticlockwise direction, the spindle is raised up. This will be raised up. This will raise the valve from its seat. Thus a passage for the steam from the clearance between the valve and valve seat is formed. To lower the valve, the handwheel is rotated in a clockwise direction. This rotation will close the passage for steam. This can be regulated by adjusting the position of the valve based on the requirements. Under the normal working condition, the valve is open and steam flows from the boiler to the steam pipe.

Function:- It is used to control the supply of water to the boiler and to prevent the escaping of water from the boiler when the pump pressure is less or the pump is stopped.

Function:- It is used to control the supply of water to the boiler and to prevent the escaping of water from the boiler when the pump pressure is less or the pump is stopped.

Construction:- This is a non-return valve placed as near to the boiler as possible.

As shown in the figure, C is the check valve. The lift of the valve is controlled by an extension of the spindle of the screw-down valve V above it. V is the feed valve. A is the flange. It is bolted to the front end of the boiler shell. It is bolted at the point from which an internal pipe leads the feed water. This water is distributed to the boiler. H is the handwheel. This is used to control the positions of the valves. The construction above valve V is similar to that of the steam stop valve.

Working:- Under the normal working condition, the pressure on the feed pump side (connected to elbow E) is more than the boiler side pressure. This pressure difference lifts the check valve C. To allow the feed water to enter the boiler, the feed valve V is lifted manually by the wheel (H) and screw (S). Hence, the feed water may enter the boiler. To control the supply of feed water to the boiler, the position of the feed valve V is controlled. In the event of failure of the feed pump, the pressure on the water sump side reduces. The check valve C will be closed because of higher steam pressure. This will prevent the backflow of water from the boiler to the water sump. The check valve is to be replaced if it does not give satisfactory results. The stuffing box is provided in the valve to stop the leakage at the spindle.

Functions:

Functions:

(1) To discharge a portion of water when the boiler is in operation to blow out mud, scale or sediments periodically.

(2) To empty the boiler, when necessary for cleaning, inspection, and repair.

Construction:

It is fitted on the boiler shell directly or to a short branch pipe at the lowest part of the water space. This pipe is known as a blowdown pipe.

The figure shows a blow-off cock. It is very commonly used with all types of boilers. It consists of plug P. This plug P is made of Gunmetal. A rectangular slot is cut in this plug. This plug fits into hollow conical body B. Asbestos packing is provided at the top and bottom in the clearance groove. This plug can be rotated. A Shank S on the yop of the plug passes through the gland and a stuffing box G. Y. is a yoke. It is fitted on the top of the shank S. This yoke keeps the plugin its position with the help of studs T. The top of the shank has a square guide. The wheel is fitted in this square guide.

Working:- To operate the valve, the rectangular slot is brought in line with the passage of the body. This is possible by rotating the plug with the help of a wheel. When the slot is placed in this position, the cock is opened and all the impurities, mud, sediments, etc. start flowing out of the boiler and they are removed. When the slot is brought at right angles to the passage (as shown in Fig.) of the body, the clock is closed.

Function:- Its function is to protect the boiler against damage due to overheating for low water level.

Function:- Its function is to protect the boiler against damage due to overheating for low water level.

Where it is fitted?

It is fitted in the crown plate of the furnace or firebox at the appropriate place.

Construction:

A common form of the fusible plug is shown in Fig It consists of a hollow gun-metal plug (A). This body is screwed into the furnace crown (B). The body has a hexagonal flange (E). This is used to tighten the body into the shell. The spanner can be used for fixing or removing it. A gunmetal plug (H) having a hexagonal flange (H) is screwed into the gun-metal body. The second hollow gun-metal plug (C), screwed into body (E) D is a third hollow gunmetal plug as shown in Fig. These two plugs are separated by an annulus of fusible metal (F). The inner surface of (C) and the outer surface of (D) are grooved such that, when fusible mental (F) is poured in (C) and (D) are locked together.

Working - In the normal working conditions of the boiler, the fusible plug is fully submerged underwater. This is so because, under normal conditions, the proper water level is maintained and can be checked by the water level indicator. Under the circumstances, the heat from the fusible plug is being conducted to water. This keeps the fusible metal at an almost constant temperature, much below its melting point. When the water level falls below the fusible plug, the plug gets uncovered from water. The upper portion of the plug gets exposed to the steam space. The steam cannot keep the plug cool. This will overheat the fusible metal The plug falls down along with the fusible metal making a hole. The steam and water, being under pressure immediately reach the firebox and extinguish the fire. The attendant is cautioned against overheating and burning of the fire tubes etc. Before starting the boiler again the operator fixes a new fuse. The fusible plug should be renewed generally after about two years as they are liable to become defective over a long period of use One plug is provided for each furnace.

There are four types of safety valves generally fitted on a boiler :

(a) Dead-Weight Safety Valve

(b) Lever-Weight Safety Valve

(c) Spring Loaded Safety Valve

(d) High Steam and low-water safety Valve

The spring-loaded safety valve is used with locomotive and marine boilers. The other types of valves are used with stationary boilers.

Construction :

Construction :

The figure illustrates a Dead Weight Safety valve. G is a bottom flange. The flange is directly fitted on the steam space of the boiler shell.

This flange carries a vertical steel pipe C. The steam exerts pressure through this pipe. A is the valve. This valve rests on the valve seat B. This valve seat is fixed to the top of the vertical pipe C. This valve has an enclosed discharge which leads the escaping steam to a pipe, connected to the discharge casing H. This casing carries the steam to a convenient point outside the boiler house.

The valve seat is fixed down by a ring casing M and screws as shown in Fig. (only one screw is shown for conveniences.) The securing ring has feathers S cast on to it which act as guides for the valve A. D is a weight carrier. It is suspended from the top of the valve. The weights E are C.I rings. These rings are enclosed in the Cl. case or cover. The load on the valve consists of (a) weight of the carrier (5) Weight of the rings (c) Weight of the cover. (d) Weight of the valve. This load balances the total steam pressure on the valve when it is blowing off. Two-step screws 'K' on the casing is provided to stop the blowing off of the valve in case the steam pressure is more than the predetermined pressure and the valve lifts from its seat. This is necessary for the event of the rush of wet steam due to priming At P, Pipe is connected for draining the casing

Working: The valve will stick to its sent B, as long as the pressure exerted on the vale A is less than the predetermined value. When the pressure exerted by the steam on the valve becomes more than the predetermined value, the valve is lifted from its seat. This predetermined value of pressure is adjusted by the force acting from above the weights etc. Because of the lifting of the valve, the steam will go to the atmosphere through the discharge pipe H. The valve comes back to its seat when the upward steam pressure is less than the downward force exerted by the weights, etc. This will help to maintain constant pressure inside the boiler shell.

2 Give a quite and satisfactory operation.

3. From the pressure adjustment viewpoint, it can not be easily tempered.

2. Because of the requirement of a large amount of weight to balance steam pressure, this valve is not suitable for use on the high-pressure boiler.

Construction:- A good design of this type of valve is shown in the figure. The valve consists of a C.I. OR cast steel body B. The flange is required to fit this C.I. body on the boiler with the help of bolts (not shown in figure 6.14). A gun-metal seat S is fixed to the top of the valve body. It is possible to replace the seat as and when required. V is a gun-metal valve. It rests on the seat S. C is a lever made from wrought iron or mild steel. The lever has its fulcrum at F. This lever is loaded by the weight W. The thrust is transmitted to the valve through the short hinged strut R. To prevent corrosion, the pins of the pin joints are made of gunmetal. Alternatively, the holes in the lever are bushed with gun-metal and in that case, the pins are made from mild steel. The pins

Construction:- A good design of this type of valve is shown in the figure. The valve consists of a C.I. OR cast steel body B. The flange is required to fit this C.I. body on the boiler with the help of bolts (not shown in figure 6.14). A gun-metal seat S is fixed to the top of the valve body. It is possible to replace the seat as and when required. V is a gun-metal valve. It rests on the seat S. C is a lever made from wrought iron or mild steel. The lever has its fulcrum at F. This lever is loaded by the weight W. The thrust is transmitted to the valve through the short hinged strut R. To prevent corrosion, the pins of the pin joints are made of gunmetal. Alternatively, the holes in the lever are bushed with gun-metal and in that case, the pins are made from mild steel. The pins

must be an easy fit in the lever.

The load W is fixed to the lever by a pin and padlock as shown in the figure. G is a fork It acts as a lateral guide to the lever. This fork G is generally bridged over the lever at the top. This is necessary to prevent the blowing of the valve in the case of in case of breaking of the lever or removal of the weight.

Working:

The valve will close the opening by sticking to its seat S, as long as the upward pressure exerted by the steam on the valve V remains less than the predetermined value adjusted by weights, weight carrier, and lever. When the steam pressure becomes more than this predetermined value, the valve V is lifted from seat S. The leakage will reduce the steam pressure in the boiler. When the upward pressure is of the steam on the valve becomes less than the valve V comes back to its seat.

Use: This type of valve is used only with the stationary types of boilers.

Disadvantages: The disadvantages of this valve are

(i) It is possible of tempering with this valve by placing a piece of wood or metal on the lever under the bridge.

(ii) The effect of a small addition to the weight is magnified considerably in its action on the valve.

Construction: The valve shown in Fig. was introduced by Mr. John Ramsbottom on British Railways. Hence it is also known as the Ramsbottom safety valve.

Construction: The valve shown in Fig. was introduced by Mr. John Ramsbottom on British Railways. Hence it is also known as the Ramsbottom safety valve.

As shown in the figure, there are two Valves V of the same size. These valves are placed on their seat in the upper ends of two hollow standards C. These standards are united by bridge B and a flange or base A. This valve is fitted to the steam space of the boiler shell with the help of base A. It is fitted on the top of the boiler, over fire-box. The valves V are held down by the helical spring S. This spring is made of round or square spring steel wire. This spring is in tension. The valve is also held down by lever L. The lever has two pivots P and Q. P is joined to the lever by pin while Q is forged on the lever. These conical pivots rest on two respective valves and force them to remain on their seats.

The upper end of the spring is hooked to an arm R of the lever, midway between the valves. The lower end of the spring is hooked to the shackle D This shackle is fixed to the Bridge as shown in the figure. Two links E are provided in the valve to prevent the valves from being blown away in the event of the spring breaking. These links are provided on either side of the lever. These links are connected with the help of pins as shown in the figure. The lower pin passes through the shackle D while the upper pin passes through a slot in the arm R of the lever. The lever L has an extension to the right. Hence it may be lifted or pull down to test whether the valves are free to act properly or not.

Working:- The valves are lifted from their seats and allow the steam to escape to the atmosphere when the pressure of steam inside the boiler shell exceeds the normal working pressure. The valve will remain in an open position until the pressure falls below the specified limit. The valves are brought back to rest on their seats by the spring force.

Advantages :

(1) It is not affected by jerks and vibrations

(2) Heavyweights are eliminated.

(3) Maintenance and examination are easy.

Disadvantage: As the valve opens the force exerted by the spring increases. This defect is eliminated by using a long spring.

Use: This type of valve is most suitable for portable

4. Feed Check Valve

Construction:- This is a non-return valve placed as near to the boiler as possible.

As shown in the figure, C is the check valve. The lift of the valve is controlled by an extension of the spindle of the screw-down valve V above it. V is the feed valve. A is the flange. It is bolted to the front end of the boiler shell. It is bolted at the point from which an internal pipe leads the feed water. This water is distributed to the boiler. H is the handwheel. This is used to control the positions of the valves. The construction above valve V is similar to that of the steam stop valve.

Working:- Under the normal working condition, the pressure on the feed pump side (connected to elbow E) is more than the boiler side pressure. This pressure difference lifts the check valve C. To allow the feed water to enter the boiler, the feed valve V is lifted manually by the wheel (H) and screw (S). Hence, the feed water may enter the boiler. To control the supply of feed water to the boiler, the position of the feed valve V is controlled. In the event of failure of the feed pump, the pressure on the water sump side reduces. The check valve C will be closed because of higher steam pressure. This will prevent the backflow of water from the boiler to the water sump. The check valve is to be replaced if it does not give satisfactory results. The stuffing box is provided in the valve to stop the leakage at the spindle.

5. Blow off Cock Valve

(1) To discharge a portion of water when the boiler is in operation to blow out mud, scale or sediments periodically.

(2) To empty the boiler, when necessary for cleaning, inspection, and repair.

Construction:

It is fitted on the boiler shell directly or to a short branch pipe at the lowest part of the water space. This pipe is known as a blowdown pipe.

The figure shows a blow-off cock. It is very commonly used with all types of boilers. It consists of plug P. This plug P is made of Gunmetal. A rectangular slot is cut in this plug. This plug fits into hollow conical body B. Asbestos packing is provided at the top and bottom in the clearance groove. This plug can be rotated. A Shank S on the yop of the plug passes through the gland and a stuffing box G. Y. is a yoke. It is fitted on the top of the shank S. This yoke keeps the plugin its position with the help of studs T. The top of the shank has a square guide. The wheel is fitted in this square guide.

Working:- To operate the valve, the rectangular slot is brought in line with the passage of the body. This is possible by rotating the plug with the help of a wheel. When the slot is placed in this position, the cock is opened and all the impurities, mud, sediments, etc. start flowing out of the boiler and they are removed. When the slot is brought at right angles to the passage (as shown in Fig.) of the body, the clock is closed.

6. Fusible Plug

Where it is fitted?

It is fitted in the crown plate of the furnace or firebox at the appropriate place.

Construction:

A common form of the fusible plug is shown in Fig It consists of a hollow gun-metal plug (A). This body is screwed into the furnace crown (B). The body has a hexagonal flange (E). This is used to tighten the body into the shell. The spanner can be used for fixing or removing it. A gunmetal plug (H) having a hexagonal flange (H) is screwed into the gun-metal body. The second hollow gun-metal plug (C), screwed into body (E) D is a third hollow gunmetal plug as shown in Fig. These two plugs are separated by an annulus of fusible metal (F). The inner surface of (C) and the outer surface of (D) are grooved such that, when fusible mental (F) is poured in (C) and (D) are locked together.

Working - In the normal working conditions of the boiler, the fusible plug is fully submerged underwater. This is so because, under normal conditions, the proper water level is maintained and can be checked by the water level indicator. Under the circumstances, the heat from the fusible plug is being conducted to water. This keeps the fusible metal at an almost constant temperature, much below its melting point. When the water level falls below the fusible plug, the plug gets uncovered from water. The upper portion of the plug gets exposed to the steam space. The steam cannot keep the plug cool. This will overheat the fusible metal The plug falls down along with the fusible metal making a hole. The steam and water, being under pressure immediately reach the firebox and extinguish the fire. The attendant is cautioned against overheating and burning of the fire tubes etc. Before starting the boiler again the operator fixes a new fuse. The fusible plug should be renewed generally after about two years as they are liable to become defective over a long period of use One plug is provided for each furnace.

7. Safety Valves

Function:- It is a device attached to the steam space of the boiler shell, which opens automatically to discharge some steam and to prevent the steam pressure inside the boiler to exceed.There are four types of safety valves generally fitted on a boiler :

(a) Dead-Weight Safety Valve

(b) Lever-Weight Safety Valve

(c) Spring Loaded Safety Valve

(d) High Steam and low-water safety Valve

The spring-loaded safety valve is used with locomotive and marine boilers. The other types of valves are used with stationary boilers.

7.1 Dead-weight Safety Valve

This valve is used only with the stationary type of boilers. It is the most elementary type of safety valve.

The figure illustrates a Dead Weight Safety valve. G is a bottom flange. The flange is directly fitted on the steam space of the boiler shell.

This flange carries a vertical steel pipe C. The steam exerts pressure through this pipe. A is the valve. This valve rests on the valve seat B. This valve seat is fixed to the top of the vertical pipe C. This valve has an enclosed discharge which leads the escaping steam to a pipe, connected to the discharge casing H. This casing carries the steam to a convenient point outside the boiler house.

The valve seat is fixed down by a ring casing M and screws as shown in Fig. (only one screw is shown for conveniences.) The securing ring has feathers S cast on to it which act as guides for the valve A. D is a weight carrier. It is suspended from the top of the valve. The weights E are C.I rings. These rings are enclosed in the Cl. case or cover. The load on the valve consists of (a) weight of the carrier (5) Weight of the rings (c) Weight of the cover. (d) Weight of the valve. This load balances the total steam pressure on the valve when it is blowing off. Two-step screws 'K' on the casing is provided to stop the blowing off of the valve in case the steam pressure is more than the predetermined pressure and the valve lifts from its seat. This is necessary for the event of the rush of wet steam due to priming At P, Pipe is connected for draining the casing

Working: The valve will stick to its sent B, as long as the pressure exerted on the vale A is less than the predetermined value. When the pressure exerted by the steam on the valve becomes more than the predetermined value, the valve is lifted from its seat. This predetermined value of pressure is adjusted by the force acting from above the weights etc. Because of the lifting of the valve, the steam will go to the atmosphere through the discharge pipe H. The valve comes back to its seat when the upward steam pressure is less than the downward force exerted by the weights, etc. This will help to maintain constant pressure inside the boiler shell.

Merits of dead weight safety valve:

1. Simple in design.2 Give a quite and satisfactory operation.

3. From the pressure adjustment viewpoint, it can not be easily tempered.

Demerits:

1. Unsuitable for any boiler subjected to vibration and movement (ie. Locomotive boiler)2. Because of the requirement of a large amount of weight to balance steam pressure, this valve is not suitable for use on the high-pressure boiler.

7.2 Lever Loaded Safety Valve:

must be an easy fit in the lever.

The load W is fixed to the lever by a pin and padlock as shown in the figure. G is a fork It acts as a lateral guide to the lever. This fork G is generally bridged over the lever at the top. This is necessary to prevent the blowing of the valve in the case of in case of breaking of the lever or removal of the weight.

Working:

The valve will close the opening by sticking to its seat S, as long as the upward pressure exerted by the steam on the valve V remains less than the predetermined value adjusted by weights, weight carrier, and lever. When the steam pressure becomes more than this predetermined value, the valve V is lifted from seat S. The leakage will reduce the steam pressure in the boiler. When the upward pressure is of the steam on the valve becomes less than the valve V comes back to its seat.

Use: This type of valve is used only with the stationary types of boilers.

Disadvantages: The disadvantages of this valve are

(i) It is possible of tempering with this valve by placing a piece of wood or metal on the lever under the bridge.

(ii) The effect of a small addition to the weight is magnified considerably in its action on the valve.

7.3 Spring Loaded Safety Valve

As shown in the figure, there are two Valves V of the same size. These valves are placed on their seat in the upper ends of two hollow standards C. These standards are united by bridge B and a flange or base A. This valve is fitted to the steam space of the boiler shell with the help of base A. It is fitted on the top of the boiler, over fire-box. The valves V are held down by the helical spring S. This spring is made of round or square spring steel wire. This spring is in tension. The valve is also held down by lever L. The lever has two pivots P and Q. P is joined to the lever by pin while Q is forged on the lever. These conical pivots rest on two respective valves and force them to remain on their seats.

The upper end of the spring is hooked to an arm R of the lever, midway between the valves. The lower end of the spring is hooked to the shackle D This shackle is fixed to the Bridge as shown in the figure. Two links E are provided in the valve to prevent the valves from being blown away in the event of the spring breaking. These links are provided on either side of the lever. These links are connected with the help of pins as shown in the figure. The lower pin passes through the shackle D while the upper pin passes through a slot in the arm R of the lever. The lever L has an extension to the right. Hence it may be lifted or pull down to test whether the valves are free to act properly or not.

Working:- The valves are lifted from their seats and allow the steam to escape to the atmosphere when the pressure of steam inside the boiler shell exceeds the normal working pressure. The valve will remain in an open position until the pressure falls below the specified limit. The valves are brought back to rest on their seats by the spring force.

Advantages :

(1) It is not affected by jerks and vibrations

(2) Heavyweights are eliminated.

(3) Maintenance and examination are easy.

Disadvantage: As the valve opens the force exerted by the spring increases. This defect is eliminated by using a long spring.

Use: This type of valve is most suitable for portable