Cochran boiler is one of the best types of vertical multi-tubular boiler. Cochran boiler is a fire tube boiler. It is a popular portable boiler. It occupies a very small floor area.

Table of content

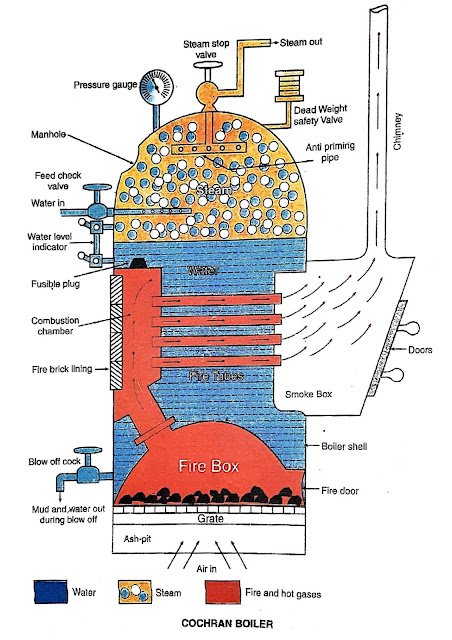

- A figure of Cochran Boiler

- Characteristics of the boiler

- Construction of Cochran boiler

- Working of the Cochran Boiler

- Advantages and disadvantages of Cochran boiler

A figure of Cochran Boiler

Specifications: the Specifications of one such boiler are as under

- Shell diameter

- Height

- Working pressure

- Steam capacity

- Heating surface area

- Efficiency

Characteristics of the boiler

- It is vertical

- it is not portable

- it is a fire tube boiler

- the number of tubes is more

- it is internally fired

- it has a natural circulation

- reliable as well as liquid fuel can be burnt

- it is horizontal tube boiler

Construction of Cochran boiler

1. Cylindrical shell

consists of a vertical, cylindrical shell. At the bottom of the FireBox is provided.

2. Firebox

The top of the boiler shell, as well as that of the firebox and, are hemispherical. It is the unique feature of the border. These shapes require less material with Maximum strength and volume. The firebox consists of the grate.

3. Grate

it is used as a platform in the Furnace. It is provided with a fire door or hole on one side of the box for adding coal.

4. Ashpan or pit

Ashpan or pit is provided below the grate. The ash pan collects the produced by the burning of coal.

5. Flue pipe

The top of the firebox carries a short flue pipe through which hot gases pass with considerable velocity to enter the combustion chamber.

6. Combustion chamber

The combustion chamber mainly consists of horizontal flue tubes. Fire bricks lining is provided on one side of the combustion chamber. The lining deflects the hot gases coming from the firebox and directs them towards horizontal flue tubes. On the other side of the combustion chamber, a smoke chamber is provided.

7. Smoke chamber OR Box

The waste gases are collected here and then released to the chimney and then to the atmosphere.

8. Steam space

The top, hemispherical portion of the bowler is called steam space. It collects the steam generated in the boiler. The portion is fitted with the safety valve for the safety of the boiler against excessive steam pressure. Other components provided are stop valve, manhole, etc.

Read Also : All Boiler Mountings with its Functions , Construction, Working Principle, Advantages and Disadvantages , Uses

Mounting: The Following Mountings are used with this boiler

Mounting

|

Brief Function

|

1. Steam pressure gauge

|

To read steam pressure.

|

2. Water level indicator

|

To find out the water level in the boiler.

|

3. Deadweight safety valve

|

For boiler safety

|

4. Feed check valve

|

To feed the water in the boiler.

|

5. Blow-off cock

|

For taking scale and other impurities

from the boiler and to empty

the boiler when necessary

|

6. Steam stop valve

|

To stop or allow the flow of steam from the boiler.

|

7. Manhole

|

For Periodic inspection

|

8. Fusible Plug

|

To stop firing when the water level in the boiler is lower than the safe limit.

|

| 9. Anti priming pipe |

To separate suspended moisture

and allow the passage of dry

saturated steam through the steam stop valve.

|

Working of the Cochran Boiler

The water is fed into the Boiler thought the feed check valve. The level is adjusted with the help of a water level indicator. Coal is added through the fire hole or door to the grate and burnt. The hot gases produced are collected in the firebox. From the firebox, the gases pass on to the combustion chamber through the short flue pipe with considerable velocity. The fire brake lining in the combustion chamber deflects the hot gases to pass through the horizontal tubes. From here, the gas through smokes-box enters the chimney. The water evaporates, and the steam is collected at the top. The steam is taken out for utilization through the stop valve.

Advantages and disadvantages of Cochran boiler

Advantages

- the minimum floor area is required. (that is it is a compact boiler)

- The cost of contraction is low.

- It can be moved and set up readily in different locations.

- The boiler has a self-contained furnace. No brickwork setting is necessary.

- Any type of fuel can be used.

The disadvantages

- Steam rising capacity is less due to vertical design.

- Difficulty in cleaning and inspection due to vertical design.

- Capacity and pressure are limited.

- The boiler requires high headroom